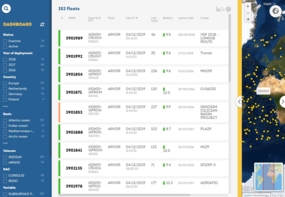

European Fleet Monitoring

A webpage has been set up that allows to display main information (metadata, CTD profiles, float trajectory on a map) on every Argo float identified by its WMO number. For some float types and versions, specific graphs are available to check float technical parameters such as battery voltage, data transmission, hydraulic behaviour, etc.

This work has started in the MOCCA project and will be enlarged to cover most of the European fleet. One can also monitor a batch of floats and access to a dashboard with important last cycle information. Several alerts and warnings regarding technical parameters have been implemented.

This work is currently ongoing and will be enhanced with the expertise of Euro-Argo national float experts and feedback from users.

The tool is accessible from the following link:

https://fleetmonitoring.euro-argo.eu/dashboard

A brief description of the website main functionalities is available here:

A user guide is available from the help page at: https://fleetmonitoring.euro-argo.eu/help

The selection of a group of floats to monitor is performed through indexes (e.g. Country, PI, Platform type, etc.). Advanced search is available from the magnifying glass button on the top left corner. The website allows the display of selected floats position on a map corner and summarises their latest cycle information in the result table.

Note: the tool has been updated in October 2019. If you encounter problems or need assistance please contact the Euro-Argo ERIC Office. Please send us any feedback you may have. Thanks!